Power Protection for Automation Applications

In this installment of Allied’s Ask the Expert Series, Siemens’ SITOP Power Supply Business Developer, Gregory Kateb, talks about power protection solutions for industrial automation applications.

In this installment of Allied’s Ask the Expert Series, Siemens’ SITOP Power Supply Business Developer, Gregory Kateb, talks about power protection solutions for industrial automation applications.

A popular trend that is growing in the US market is the use of ferrules, also known as end sleeves, to terminate single and multi-conductor wires, e.g. in the terminal blocks within a machine’s control panel. For US equipment manufacturers that export to Europe, using ferrules is a requirement to receive CE certification so that a company can do business within the European Union. Regional Sales Manager Bob Wells takes some time to answer a few questions he hears in the field about this cable termination technique.

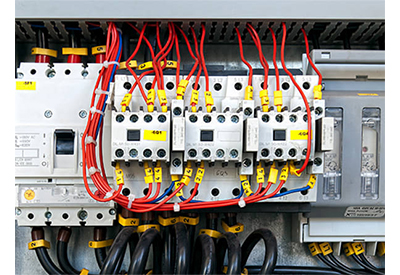

Power is vital to production, and well-designed control cabinets are key. Today, virtually every industrial application spanning the food & beverage and chemical processing industries to the oil & gas, power generation, product manufacturing, and wastewater treatment industries relies on critical — and often sensitive — powered electronic systems. These systems are vital to productivity, represent considerable investments, and pose serious safety risks, so it’s essential to keep them running safely, reliably, and efficiently.

Maintaining wastewater treatment plants is essential to meeting the critical need for clean water. In the United States alone, about 34 billion gallons of wastewater is processed each day. Much of this can be attributed to increasingly stringent, but environmentally necessary, government regulations that now require companies processing chemicals, pesticides, and other harmful materials to recover ninety-five to ninety-nine percent of water from waste streams before releasing it back into the environment.

Many business of all sizes turn to robots for the purpose of enhancing precision, speed, and consistency while minimizing expenses and downtime. However, many of them – particularly the smaller enterprises – are initially unsure of whether the payoff will be worth it. Omron provides a variety of robots to meet the specific needs of their customers. Whether you’re trying to automate highly repetetive tasks or shift some of the heavy lifting to machinery, Omron can help you choose the right technology.

Not all environments where you find cables and wires are the same. Factors to consider for cables in an IT cabinet or routed through an office building are not the same as the demands on cables that are located in an industrial setting. Harsh chemicals, oils, and other lubricants are just a few of the challenges that cables providing power or transmitting data must withstand in industrial environments to keep operations online.

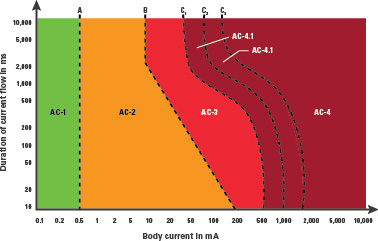

With power, comes great responsibility. A panel builder who can effectively integrate ground-fault circuit interrupters (GFCIs) into a system can make the difference between life and death. Ground-fault circuit protection is one of the most effective preventative measures against electrical shock because it actively reacts to irregular electrical conditions, regardless of a worker’s qualifications or use of personal protective equipment (PPE).

Sustained cost pressures caused by low raw material prices are forcing mining companies to seek solutions that optimize productivity and reduce costs. In order to ensure competitiveness, the tradition-steeped mining industry is relying increasingly on intelligent automation solutions. Along the entire value creation chain, from exploration and extraction of mineral resources to infrastructure and further processing to final delivery to the customer, all process steps have to be streamlined in order to ensure economically viable operation.

Signal tower lights play a critical role in protecting the safety of people and equipment in manufacturing and process control environments, providing visual and audible indications of system status and alerts of dangerous conditions. They are relatively simple devices, but until recently, they have been notoriously difficult to configure, order and stock because of the proliferation of different sizes and options to meet the wide range of applications.

A small utilityin Seguin, Texas installed a complete monitoring and control system that rivals systems installed at much larger utilities to improve service.

The May 2021 ransomware attack on JBS Foods that knocked out the plant operations supplying roughly a fifth of the United States’ meat supply is an all too familiar story. Since September of 2021, the Federal Bureau of Investigation (FBI) has been alerting food producers, processors, and manufacturers via an industry-specific notice that criminals are carrying out focused ransomware attacks targeting companies in this sector.

While digitalization has become a crucial goal across sectors, the application of digital solutions in manufacturing comes with added complications. Given the material nature of industrial process assets and equipment, the emphasis for manufacturing investment has still been predominantly hardware based, with upgrading plant machinery essential to meet production demand.

A common misconception surrounds manufacturing today: the idea that introducing robotics and other automation equipment into the picture will rapidly dry up the industry’s career opportunities. In fact, automation does the opposite – by creating even MORE demand for human intelligence and ingenuity. Building and maintaining the factory of the future requires capable individuals who enjoy solving problems and thrive on novelty.

There’s a tendency in every industry to gravitate towards, and heap excessive praise on, new technology. You can see companies of every shape and size purchasing or installing the newest tech gadget and then shouting from the nearest mountaintop about how it’s going to revolutionize their entire operation. Guess what? The control panel industry is no different — and there’s absolutely nothing wrong with that.

Derating is a protective measure which allows the use of power supplies at high temperatures, at high altitudes or in alternative mounting orientations. In this blog article you will learn what you should consider when it comes to derating. Most power supply manufacturers specify ratings for lifetime, output current, and reliability (e.g. MTBF) for their products. However, this information only applies under certain environmental conditions.

The steel industry has faced a whirlwind of challenges—a hiatus in construction projects, worldwide pandemic, supply chain disruptions, and market fluctuations—but increased demand for domestically produced steel is creating opportunities for U.S.-based manufacturers. The steel mills driving this growth are enhancing and developing their complex operations and processes to run more efficiently.