Complete Automation Overhaul Benefits Smaller Utilities

September 20, 2022

By: NovaTech Automation

Traditionally, small municipal electrical utilities like the one in the City of Seguin, Texas have believed that implementing a SCADA was simply out of reach, due to the perceived high initial costs, high licensing fees, and complexity of such systems.

However, advancements in web-based SCADA systems have transformed the process of installing, configuring, and managing such systems to manage substation performance. Modern web-based systems streamline installation and maintenance and provide engineers with a modern user interface they can easily configure – a factor that now allows even smaller cities to operate like large investor-owned utilities with hundreds of substations.

Case in point is the city of Seguin, Texas. The utility embarked on an ambitious plan to integrate a new SCADA system with Outage Management System software, citywide WIFI, advanced metering infrastructure (AMI) technology, GIS Mapping, and energy efficiency software to improve customer reliability and education. The system was designed to enable utility engineering teams to manage a dispersed network and more efficiently support the cooperative’s mission for reliable, cost-effective service.

The City of Seguin had no trouble justifying the SCADA investment even though there are only three substations. The system provides the same degree of monitoring and control system as implemented by larger utilities.

The City of Seguin has a population of 25,090. Approximately 8,200 residential customers, as well as several large industrial facilities rely on power from the electrical system. The utility operates three substations with 14 Circuits, which requires 19 employees to manage 110 miles of overhead and 26 miles of underground electric lines.

To complete this ambitious SCADA implementation, the city turned to M&S Engineering, a full-service electrical, civil, subsurface utility engineering, and surveying firm to develop all the specifications outlined in the initial bid.

For the physical infrastructure and sensors, M&S Engineering specified an AMI System from Aclara, which includes nine collectors that gather smart meter readings. AMI Systems enable electric utilities to collect and harness the power of smart meters, edge devices, and data to meet challenges such as substation monitoring, load monitoring, load control/demand response, fault detection/outage management, distributed generation, conservation voltage reduction, and customer engagement.

The data is then transmitted over a newly installed, citywide Strix WIFI system to a central network, which allows multiple users and departments to access the information.

To enhance communication and decision making, assets such as electric poles and meters are now mapped and coordinated through ESRI, a geographic information system (GIS) mapping company. The GPS coordinates facilitate more efficient dispatching of utility trucks and service crews, when needed.

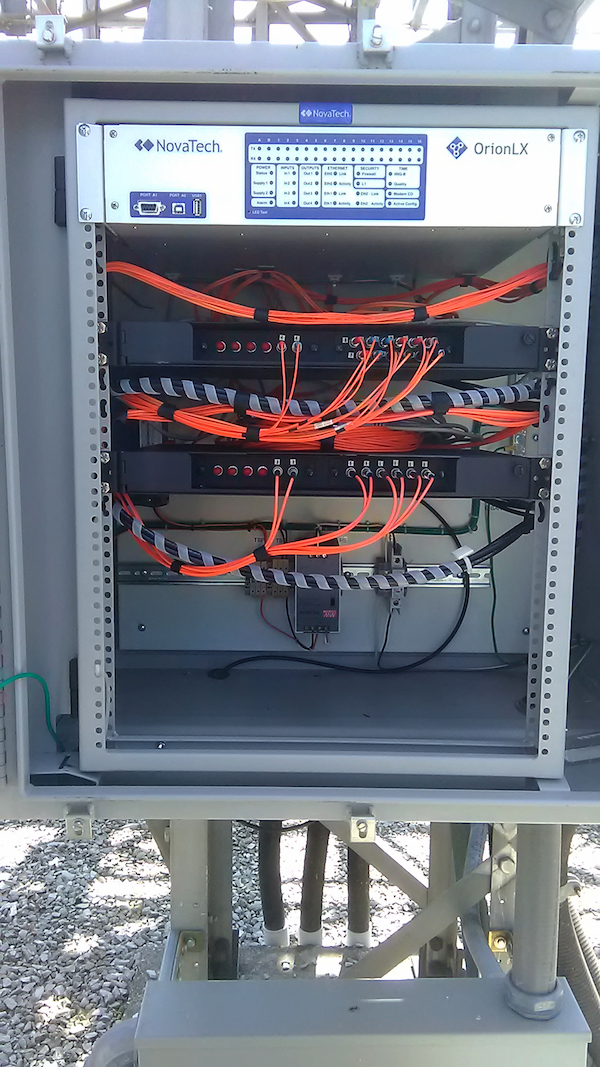

For the SCADA system, M&S Engineering selected the OrionLX system from the Power Division of NovaTech Automation (Lenexa, KS), a substation automation company that has served the power transmission and distribution market for more than 30 years.

The company’s OrionLX is a communication and automation processor that can connect to nearly any substation device in its native protocol, perform advanced math and logic, and securely present the source or calculated data to any number of clients in their own protocol. The system can be integrated with practically any equipment, usually microprocessor-based relays, meters, and other IEDs as well. It is then connected to the SCADA system.

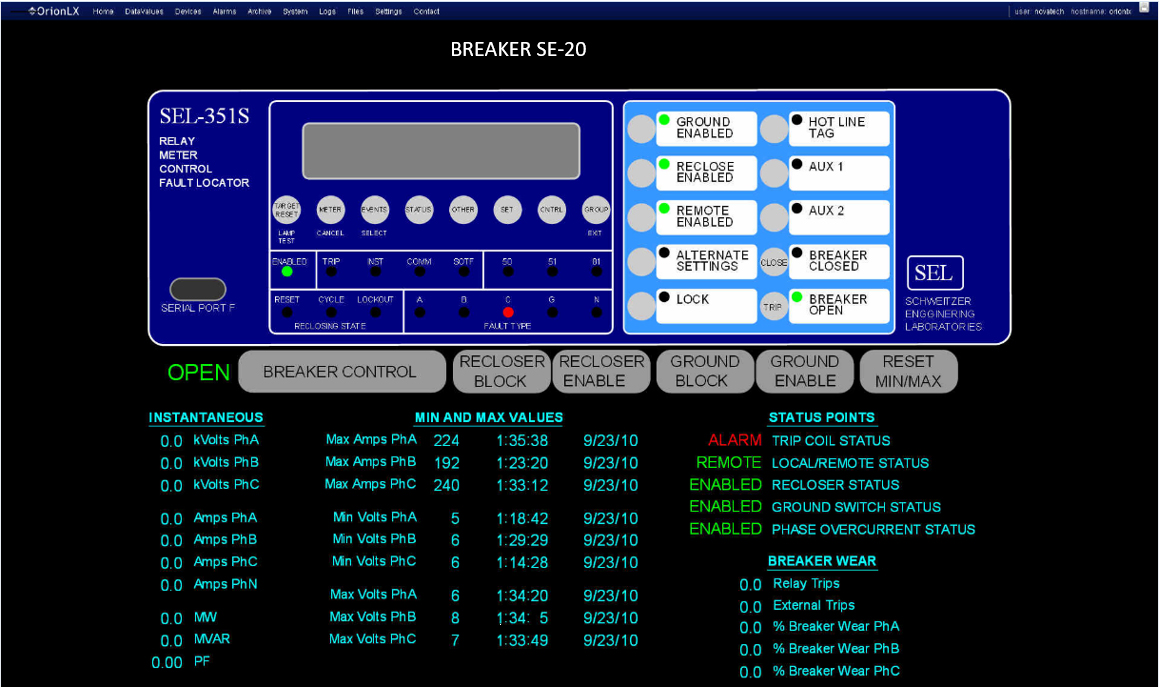

The system uses open-source web technologies and pre-configured template pages. This simplifies the building of interactive SCADA and local HMI screens to view data from connected IEDs and RTUs using standard web browsers. Engineers can open multiple browsers to have graphical interfaces for the different substations and key remote monitoring features on different tabs, which eases network monitoring. Multiple users can be logged in simultaneously.

For the most economical setup, the City of Seguin opted to install an OrionLX in each of its three substations that connect wirelessly to a browsing PC with multiple monitors, each representing a substation. Another configuration option for smaller utilities is a centralized model where an Orion is installed in the central office (taking the place of the browsing PC), where it accesses each substation OrionLX and serves up the information to connected networks.

The Orion RTU has advanced in the integration of functions previously accomplished by separate physical devices. For example, separate alarm annunciators and PCs do not have to be connected to the Orion RTU; only a monitor, keyboard, and mouse need be connected. The Orion Tile Annunciator is a pre-engineered product that can be set up in minutes to serve out alarm status. When combined with sequence of events recording, relay event retrieval, IED faceplates, one-line diagrams, IED faceplates, control screens, and trending, Orion can serve as a complete substation HMI…or an economical small SCADA system.

One-line diagrams in the Orion HMI show the status of the entire substation at a glance. This enables dispatch teams to quickly tell which feeders are open and if there are voltage issues. Feeder breaker zoom screens allow more detailed information to be viewed at the office, such as: ground trip blocked, non-reclosing, max amperage, power factor, and fault currents. See Figure 1 below. History of events can be accumulated, such as: breaker trips, breaker lock outs, reclosers blocked or enabled, low voltage events, high voltage events, and maximum amperage for each circuit.

M&S Engineering was also asked to integrate the Orion SCADA system with Milsoft’s Outage Management System (OMS). OMS are efficient at identifying locations of outages and providing real-time alerts. The systems also record the history of outages and alert customers about the status of outages and repairs.

Over time, NovaTech has received multiple requests to create an interface between their equipment and popular outage management systems. As a result, NovaTech will introduce the MultiSpeak interface in Q4 2022, which facilitates communication between enterprise applications, SCADA, outage management, dispatch, GIS, and meter reading.

As part of the project, M&S also specified an upgrade of all electromechanical relays to microprocessor relays from Schweitzer Engineering Laboratories (SEL). NovaTech developed settings that allowed the SEL relays to be accessed by the OrionLX, including real-time data and fault information.

“Relays keep detailed records of the electrical conditions at the time of a fault, and that information can be accessed remotely to provide technicians with critical information on where to go and what might need to be corrected,” says Ray Wright, Senior VP, Marketing for NovaTech.

“You don’t want to have a technician going out and searching the line for miles to find the problem and then have to go back to the shop to get the needed equipment,” he adds. “Ideally, you want to say, ‘Drive to this GPS location, bring a spare fuse, and fix the [known] problem.”

Minimizing Dispatches

After the SCADA system, microprocessor-based relays, and other components were installed, the city could respond to issues more quickly, resulting in shorter outage times for customers. Previously, personnel would have to drive out to a substation when there was an issue with a feeder or transformer. Now, most issues are diagnosed remotely.

“Now the monitoring is done from the office,” he adds. “The engineering team remotely logs into the substation devices to view the data, settings, sequence of events, and make changes if needed. They usually do not have to visit the substations in person, so the labor involved in monthly checks is significantly reduced,” says Wright.

“With SCADA, they can monitor and capture events, such as low voltage or high voltage at the bus, which helps when troubleshooting customer complaints, and enables remote manual control of voltage regulators,” says Wright. SCADA also allows the city to monitor the power factor on individual circuits and then to switch capacitors in or out, without having to depend on other companies.

In the future, the city of Seguin plans additional system upgrades, including an energy efficiency program. This includes a new VoIP phone system and approximately eight additional WIFI units along with accompanying antennas to improve “self-healing” properties. The utility is also investigating automated switching, which would involve adding control panels and motors to the existing air break switches to facility operations through the SCADA system.