B&R Automation: New ACOPOS M4 Servo Drive Sets Benchmark in Scalability, Power and Multi-Axis Control

December 8, 2025

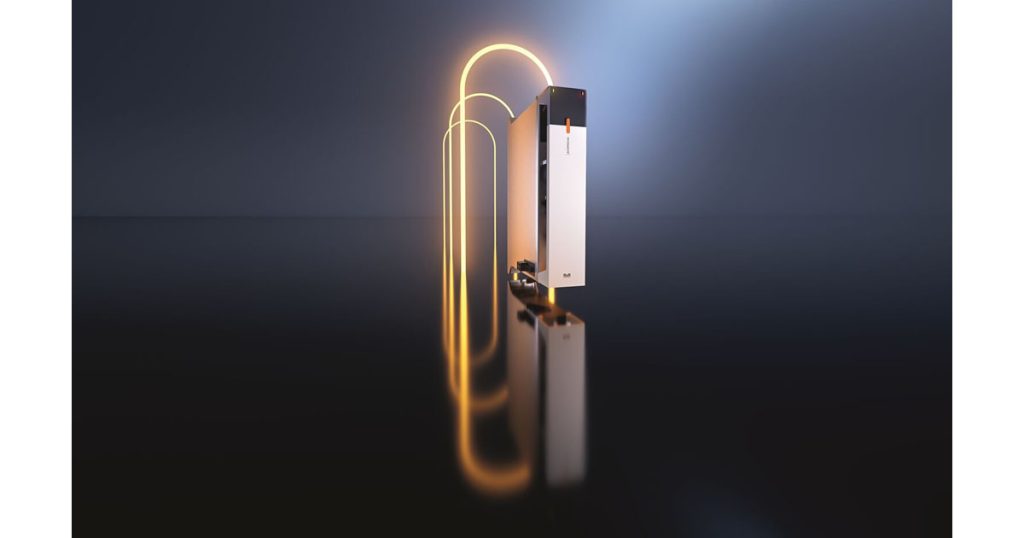

Designed with innovative power stage technology at its core, the ACOPOS M4 is the newest and most advanced servo drive by B&R, the Machine Automation Division of ABB.

The new ACOPOS M4 from B&R redefines high-performance motion control for modern manufacturing. It combines outstanding precision and power with a compact, scalable design, while tackling challenges such as predictive maintenance, scalability and machine performance.

It delivers outstanding precision, power, and efficiency, all within a compact footprint and high scalability. A new embedded system enables the implementation of predictive maintenance, allowing problems to be detected before they lead to costly errors. In addition, the ACOPOS M4 provides compatibility with the open-source OPC UA FX protocol for a secure key technology for industrial communication networks, enabling real-time communication in the industrial environment.

“ACOPOS M4 sets a new benchmark for motion control – combining compact design, energy efficiency, intelligence and OPC UA FX connectivity to deliver secure, scalable automation without limits. Up to four synchronous, asynchronous, linear or torque motors can be controlled simultaneously from one ACOPOS,” said Wilfried Guerry, Product Manager Motion at B&R Industrial Automation. “Compared to previous generations, the ACOPOS M4 doubles the power density, facilitating the design of smaller, more energy-efficient machines and cabinets. For machine builders and end users, having the ability to control more motors from a single device allows for improvements in machine capabilities and performance, without compromising on space.”

The implementation of a newly design embedded system opens up possibilities for predictive maintenance and AI functionalities. The ACOPOS M4 can detect and flag up issues to human operators long before they develop into faults. It can also sense, adapt, monitor and predict machine behavior, and respond quickly to external changes. Built-in diagnostic and maintenance tools monitor the condition and performance of the ACOPOS M4 device, while automatic firmware updates provide performance and security improvements throughout its lifetime.

A 60% reduction in cabinet footprint (for 4-axis modules) allows machine builders and systems integrators to achieve more with less. To achieve this, B&R developed a multi-level technology using standard MOSFET transistors which can deliver power supply efficiency of nearly 99%, while cutting power losses by 40%. This power supply design requires less space and cooling in the electrical cabinet. By integrating an Electromagnetic Compatibility (EMC) filter into the power supply module, while removing the need for an external braking resistor or regeneration choke, the configuration length of ACOPOS M4 is reduced by 30% (for a 12-axis-configuration).

Combined with the device’s high efficiency, this also allows cabinet cooling requirements to be downsized to further optimize cabinet space. Within the ACOPOS M4 range, both water-cooled and air-cooled variants will be available, from 1.4 kW (1.9 A) to 200 kW (315 A).

The ACOPOS M4 is developed natively on OPC UA FX. It is designed to unlock the full potential of this next-generation fieldbus for future, truly plug-and-produce machine automation with its outstanding performance combined with the openness of OPC UA FX. It is an extension of OPC UA, which is designed specifically to be cross-platform and open-source, allowing integration of field level devices all the way up to cloud applications. It enables more reliable control networks and, at the same time, allows secure data collection from multiple systems at the same time.

OPC UA FX also includes certificate-based encryption, providing a more robust security environment, compared to integrating several different protocols at once. Building on the proven reliability of previous ACOPOS generations and incorporating multi-level topology with patented firmware features, the ACOPOS M4 power supply module pushes performance even further.

“We are extremely proud of the power efficiency and compactness we’ve achieved with the ACOPOS M4,” said Wilfried Guerry. “We can offer our customers a disruptive technology for industrial automation, a solution that not only fits their needs but can be adapted and scaled in the future.”

- Benefits for machine builders and end users:

- Increased power in a smaller footprint

- Optimization of cabinet space

- OPC UA FX allows flexibility in communication

- Improved energy efficiency

- In-built functionalities reduce need for external devices

- Enhanced condition monitoring of device and wider processes