Revolutionizing Robotic Food Handling with Circular Connectors

July 7, 2025

Food and beverage production is evolving to become faster, cleaner, and more automated than ever. From robotic arms to high-speed conveyor systems, reliable connectivity is the backbone of next-gen equipment. Discover how circular connectors are enabling high-performance automation in even the most demanding hygienic environments. Designed to withstand frequent washdowns, extreme temperatures, and aggressive cleaning agents, today’s circular connectors ensure uninterrupted signal and power transmission under rigorous operating conditions.

As production lines become more intelligent and integrated, the right connectivity solutions are essential for maintaining uptime, improving efficiency, and meeting strict industry standards for hygiene, safety, and long-term performance.

Market Evolution & Industry Challenges

The food and beverage industry is under increasing pressure to deliver higher output, minimize contamination risks, and reduce reliance on manual labor, all while maintaining compliance with stringent regulatory standards. To meet these demands, manufacturers are rapidly adopting advanced robotics and automation technologies.

However, the effectiveness of these systems depend on the reliability of every component involved. From harsh washdown zones to dynamic motion applications, connectors and cabling must be engineered to withstand the unique stresses of hygienic production environments. Only with purpose-built, high-performance components can automation deliver the speed, precision, and cleanliness the modern market requires.

Key Challenges:

- Labor shortages driving demand for automation

- Strict hygiene regulations (FDA, Ecolab)

- Frequent washdowns and chemical exposure

- Rapid changeovers requiring quick disconnect systems

Circular connectors are playing an essential role in enabling flexible, hygienic automation without compromising uptime or safety.

The Hidden Backbone of Food Automation: Why Connectivity Matters in Robotic Food Handling

In highly automated systems, every connection counts. Circular connectors ensure uninterrupted communication and power transmission between control units, robotic end-effectors, sensors, and actuators. This matters even in extreme food-processing conditions. Exposure to moisture, aggressive cleaning agents, temperature fluctuations, and mechanical vibrations can compromise performance if components are not properly engineered. Robust circular connectors, designed with hygienic housing and IP-rated sealing, safeguard data and power integrity in these environments. By maintaining consistent performance under stress, they enable robotic systems to operate with precision, reduce unplanned downtime, and uphold the strict hygiene and safety standards essential in modern food production.

In F&B environments, connectors for robotic applications must be:

- Compact and vibration-resistant

- Easily mated and unmated for fast tool changes

- Resistant to high-pressure water jets and cleaning agents

- Capable of maintaining signal integrity during dynamic motion

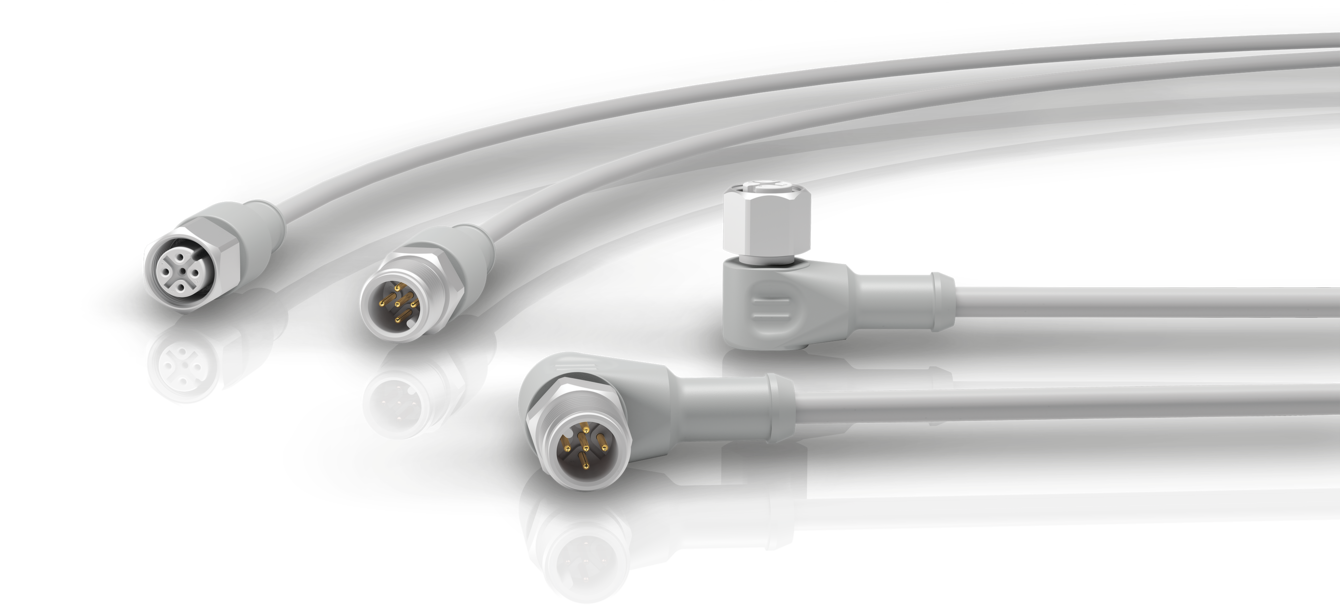

F&B Circular Connectors: Clean and hygienic by Design

Purpose-built for food and beverage environments, circular connectors offer sealed housing, stainless-steel locking elements, and smooth, easy-to-clean surfaces which are key features for avoiding bacterial harborage and maintaining uptime.

Hygienic Engineering Features:

- IP67 to IP69K sealing for full washdown resistance

- Stainless steel threads and locking mechanisms

- Smooth contours to prevent residue buildup

- Ecolab-certified resistance to industrial cleaners

- Broad temperature range (–40°C to +85°C)

Compliance Comes Standard: Built for Audit-Ready Performance

Regulatory compliance is not optional in food processing. Our circular connectors are designed to help OEMs and integrators meet the strictest hygiene and safety standards.

Supports Compliance With:

- FDA-grade materials

- RoHS and REACH compliant

- Ecolab and FDA Compliant

- Special TPE and PVC cables

- IP69K ingress protection

- IEC, CE and UL standards for industrial automation

Where Circular Connectors Excel in Robotic Food Handling

- Robotic Arms: Enable flexible, repeatable movements with washdown-capable connectors for grippers and wrist joints

- Packaging & Sorting: Power and signal to decentralized I/O systems for high-speed conveyors

- End-of-Arm Tooling: Quick-release designs allow rapid changeovers and sanitation

- Pick-and-Place Units: Compact connectors support lightweight, high-precision designs

- Tray Loaders & Palletizers: Rugged interfaces minimize downtime from vibration and impacts

https://www.binder-connector.com/en/news/circular-connectors-in-robotic-food-handling