Food Portioning in Accordance With PL e

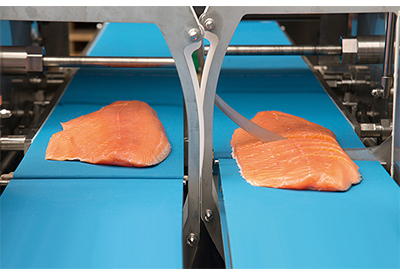

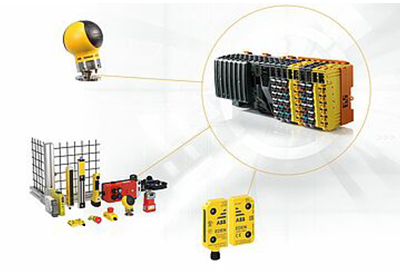

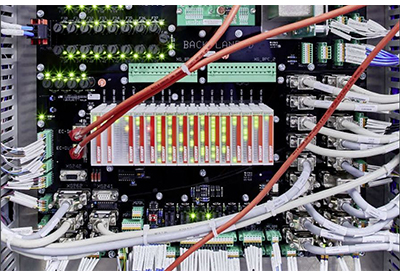

The Belgian machine builder Marelec develops machinery for portioning processes, in which meat or fish is sliced into portions of an exact, specified weight. These machines from the “Portio” series have a minimum of 17 cutting movements per second. To ensure they are not only highly productive but also safe, Pilz developed an appropriate safety concept to Performance Level PL e.