Beckhoff: 40 Years of Innovations

How can new machine and plant concepts that are superior to conventional solutions in terms of sustainability, flexibility, and efficiency be implemented in packaging? As a long-standing automation partner to the packaging industry,

The county of covers more than 20,000 square miles and comprises 24 cities encompassing more than 2 million residents. In fact, San Bernardino is the largest county in the United States. For the county’s facilities management staff, responding to a service call for one of the county’s many buildings meant spending several hours on the road and using many gallons of fuel. By taking a proactive approach with Siemens, the county has become more sustainable and energy efficient.

The continued growth and development of AI means an increased need for powerful data centers to process and store large amounts of data. More than 60% of data center operators are preparing to increase the number of IT racks in their data center installations to properly handle the growing workload. This article will look at how high-density data centers work and the kinds of IT racks, cooling units, and accessories operators need to achieve the greatest possible performance with this kind of data center.

Keeping employees safe at work has to be responsibility number one for a company. What is the rationale for being profitable if unsafe, or delivering product quickly to the customer if the workplace is unsafe and so everyone agrees that workplace safety is a priority but then we need to ask why are the incident rates of electrical injuries and in some case fatalities not reducing year over year, if keeping employees safe is a priority?

It’s been a little over a year since ChatGPT arrived on the scene and put the future of artificial intelligence in the spotlight. Top of mind were risks. Questions were heard such as: Are technologies becoming too powerful? Is AI advancing too rapidly – faster than we’re prepared for? These questions are now prompting important conversations between government and industry. Collaboration will be needed not only to guard against risks but to seize the many positive opportunities ahead.

Panel building on machine tools is no longer as simple as wiring a few components and calling it a day. Now, there are more deadlines, cost pressures, standards, new directives, plus an increasing pressure to innovate. Besides commonly encountered problems related to time, cost, compliance and quality, there is also an increased degree of automation in the pre-fabrication of cables and the automated production of sheet metal parts.

This webinar presented by Beth Lessard and Keith Cordero will be highlighting three Panduit solutions that will optimize network equipment and cabling to ensure that your spaces are efficiently and properly managed to support ever-evolving business needs of today and beyond. Products that will be featured include PanZone TrueEdge Wall Mount Enclsoure, Cable Managers, and Adjustable Depth 4-Post Rack.

The Siemens SIMOVAC medium-voltage non-arc-resistant and SIMOVAC-AR arc-resistant controllers have a modular design incorporating up to two 12SVC400 (400 A) controllers, housed in a freestanding sheet steel enclosure. Each controller is UL 347 class E2, equipped with three current-limiting fuses, a non-load-break isolating switch, and a fixed-mounted vacuum contactor (plug-in type optional for 12SVC400). The enclosure is designed for front access, allowing the equipment to be located with the rear of the equipment close to a non-combustible wall.

Power is vital to production, and well-designed control cabinets are key. Allied Electronics & Automation offers a comprehensive collection of control cabinet solutions including PLCs, HMIs, contactors, miniature circuit breakers, terminal block connectors, DIN-rail power supplies, pushbutton switches, motor starters, overloads, power relays, industrial Ethernet switches and AC drives engineered to keep your operations running safely, reliably and efficiently.

Learn more HERE.

Weidmuller USA has revolutionized cabinet building with the release of the Online Weidmuller Configurator (WMC), an innovative web-based tool that makes designing DIN rail configurations fast, easy and accessible anywhere, on any device. Read More…

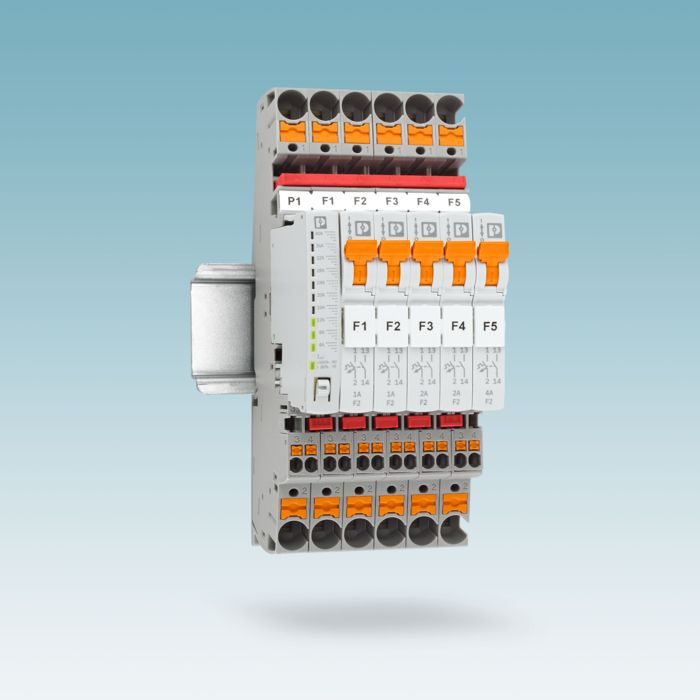

Narrow circuit breakers from Phoenix Contact offer more space in the control cabinet Read More…