Siemens’ Tips for Panel Builders Series – Part 4: Control Panel Modeling in 3D

The manufacturing of control panels and system cabinets in particular incurs high expense and wastage when it comes to the wiring and mechanical processing of the cabinets. 3D planning offers a solution in terms of optimizing the work steps and avoiding the unnecessary waste of excess cable. For this purpose, the EPLAN range of products includes the Pro Panel software, which facilitates the 3D planning of control cabinets.

What does it offer you?

Apart from the purely 3D data, other helpful technical information is stored directly in the article macros of the Siemens devices. For example, you will find information in Pro Panel about the connections of the article to support the auto-routing function. In addition to the description and design of the connections, the global wiring diagram also stores their position in three-dimensional space as well as their routing direction. With the help of these specifications, the necessary cable lengths can be calculated to the exact millimeter directly in EPLAN on the basis of the wiring diagram project.

In addition, these values can be exported to a cable assembly machine in order to guarantee standard-compliant wiring to the exact cable length. You can show the cable-laying direction and connection designation directly in 3D by selecting View → Connection Directions or Connection Designations.

Apart from the wiring diagram, you will also find a drilling template in the Siemens article macros. These contain valuable information about the number, position and size of necessary penetrations on the mounting plate or door cutouts. This information can also be exported from EPLAN to a machine / robot, enabling all necessary penetrations to be transferred automatically to the mounting plate. You can make this visible in EPLAN by selecting View → Drill-hole view.

Then use our CAx Download Manager. This enables you to request our CAx data automatically, such as certificates, documentation, product master data and much more, for a number of articles at the same time. When your download is ready, you are notified by email containing a link to your individual download. Select the type of information “Product master data” if, for example, you require cable cross -sections or other technical specifications.

All necessary power loss data for control panel devices can be found in the Siemens Industry Online Support Portal.

On many accessory parts and basic units, mounting points are stored in the macros. These support you when assembling two components in 3D. In this way, the risk of errors can be minimized and precise placement is made possible.

Molex has recently acquired core technology and intellectual property (IP) from Keyssa Inc., a provider of high-speed contactless connectors. The acquisition of this unique wireless chip-to-chip technology, including over 350 filed patent applications, will accelerate Molex’s strategy to further expand and diversify its micro connector portfolio with highly flexible, cable-free connectors for near-field, device-to-device applications.

With SIRIUS Control, you always have the right solution at hand. SIRIUS is a modular system with a uniform design and a multitude of potential combinations. You also benefit from more than 50,000 pretested and approved combinations for the most common applications. High-quality CAx data simplifies electrical engineering and saves you time during panel building.

The rapid and error-free transfer of information is essential for efficient electrical planning. The TIA Selection Tool already provides you with extensive support in the electrical dimensioning and selection of important components. And now you can export this planning data directly to EPLAN. EPLAN will show you how this works, which components are already supported today and what the result looks like in EPLAN electric P8 using an example project.

Bel Power Solutions & Protection is proud to offer products through Sager Electronics. Bel Power Solutions & Protection, a division of Bel Fuse Inc., specializes in power products from 3 W to 25 kW for server architecture, storage, networking, and telecommunications.

ABB recently announced its plan to expand its manufacturing facility in Hackettstown, New Jersey to meet growing demand for electrical equipment. The expansion will double the solid dielectric switchgear manufacturing footprint to 24,000 square feet, bringing the total site to 120,000 square feet when complete, and will feature state-of-the-art manufacturing equipment.

The Technology Days, taking place for the first time this year, provide participants with the opportunity to talk to specialists and find out about the added value of this communication technology. A keynote, discussions, and an exhibition constitute the framework of this digital conference.

This webinar presented by Beth Lessard and Keith Cordero will be highlighting three Panduit solutions that will optimize network equipment and cabling to ensure that your spaces are efficiently and properly managed to support ever-evolving business needs of today and beyond. Products that will be featured include PanZone TrueEdge Wall Mount Enclsoure, Cable Managers, and Adjustable Depth 4-Post Rack.

The Siemens SIMOVAC medium-voltage non-arc-resistant and SIMOVAC-AR arc-resistant controllers have a modular design incorporating up to two 12SVC400 (400 A) controllers, housed in a freestanding sheet steel enclosure. Each controller is UL 347 class E2, equipped with three current-limiting fuses, a non-load-break isolating switch, and a fixed-mounted vacuum contactor (plug-in type optional for 12SVC400). The enclosure is designed for front access, allowing the equipment to be located with the rear of the equipment close to a non-combustible wall.

Power is vital to production, and well-designed control cabinets are key. Allied Electronics & Automation offers a comprehensive collection of control cabinet solutions including PLCs, HMIs, contactors, miniature circuit breakers, terminal block connectors, DIN-rail power supplies, pushbutton switches, motor starters, overloads, power relays, industrial Ethernet switches and AC drives engineered to keep your operations running safely, reliably and efficiently.

Learn more HERE.

Weidmuller USA has revolutionized cabinet building with the release of the Online Weidmuller Configurator (WMC), an innovative web-based tool that makes designing DIN rail configurations fast, easy and accessible anywhere, on any device. Read More…

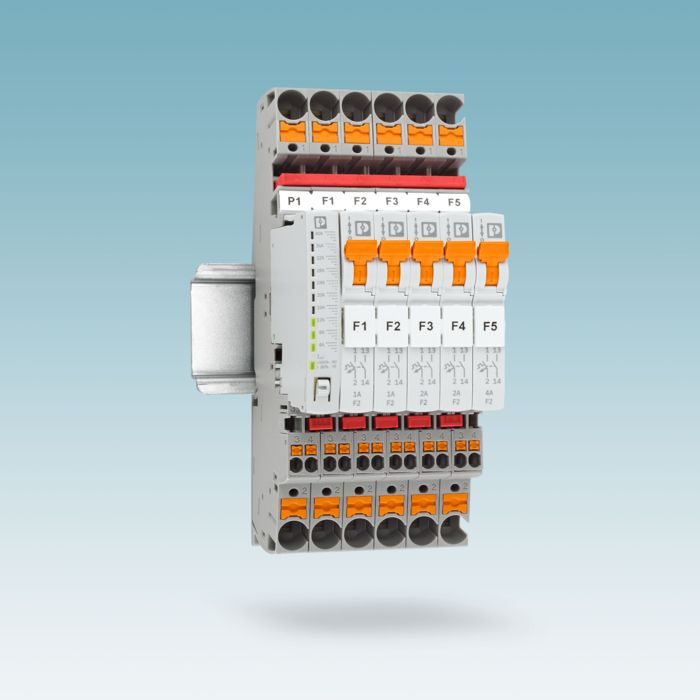

Narrow circuit breakers from Phoenix Contact offer more space in the control cabinet Read More…